Typically, laser technology came into service more than 25 years back. Since then laser technology demand is increasing day by day because it helps to produce permanent, precise, and fast laser service (laser marking, laser engraving & laser cutting) on the products rather than the traditional methods.

Laser Services Products

Water Bottle | Metal Pen | Name Plate | Diary | Note Pad |

Laser technology works digitally which is very effective in today’s digital life. If your business is involved in product manufacturing, customized branding, or crafting and you are hungry to provide precise & fast service you can go for laser marking-engraving-cutting service to your customers. A laser engraving-cutting machine might be a game changer in your business.

Types of Laser Source & Effectiveness

There are 2 types of laser sources 1. Co2 Laser, 2. Fiber Laser. Each type of laser source has its own pros and cons choose the best fit for your project.

Before buying a laser engraving machine, you need to know what types of substrate material and size you are looking for, to work on laser marking, engraving & cutting services because products are made of different types of materials & thicknesses which is why they required different power supply to produce appropriate wavelengths of laser quality.

- Products made of Paper, Bamboo, Cloth, Leather, Wood, Plastic, or Leatherette Material required a low power supply because their material density is very low.

- Where high-density metals like Steel, Iron, Brass, Copper, and Aluminum required a high power supply to engrave or cut through.

LaserPecker

This machine is the best for Laser Marking Only on Plastic, Wood, and Metals. It can’t be used for laser-cutting applications. It required a low power supply and is a kind of desktop laser-making tool. It performs best at a distance of 175mm-200mm between the focal lens & substrate. Customized branding on the metal pen, wooden trophy, and crafting works. Very handy to carry on.

| Product Specifications | |

| Best Used For | Laser Marking on Customized Gift Items |

| Resolution | 1k-4K |

| Power Supply | 5V/2A |

| Laser Speed | 5000/s |

| Engraving Speed | 6mm-600mm/s |

| Supporting Device | Android, Mac, PC |

| Laser Engraving Machine Weight | 2.54 kg |

| Engraving Area | 60mmx60mm |

| Laser Life | 10,000 hrs. |

| Type of Laser | Optic Laser |

Pros

- LaserPecker L1 Pro Suit: Added auto-adjusting support stand compared to L1 Pro Basic

- Mini Engraving Machine: Laser Unit weighs only 6.7 oz

- Easy to Use: Our laser cutter plug and play, no tedious installation required

- Widely Used: LaserPecker L1 Pro laser engraver CAN Engrave

- Safe and Guarantee: LaserPecker L1 Pro

Cons

Cut

Felt, carboard and paper within 0.5mm thickness can be cut

Reflective Materials

White, transparent, blue & reflective material can’t be engrave directly, you can mark it black and clean the paint once engrave finished

Photosensitive Stamp

Select “Seal” mode in the APP, and make your own personalized stamp

Color Engraving

Color can be sculpted with shiny coloring powders

LE400PRO

Pros

- ???? ???????: LE400 Pro laser cutter and engraver adopts spot compression laser technology

- ??? ?????????? ??????: The laser engraver machine is equipped

- ???? ?????: The focal length of the laser is a fixed value, no need to adjust the focus before engraving

- ???? ?? ????????: Full aluminum alloy modular can typically be assembled in 20 minutes

- ???? ?????????????: The laser engraving machine can be compatible with LaserGRBL, LightBurn

Cons

Why is the KENTOKTOOL LE400 Pro Laser Engraver Unique?

The most advanced technology – Using the most advanced spot technology, the laser focus spot is as fine as 0.08mm² and 2 times thinner than ordinary lasers.

Insist on innovative design – In the design of the laser protective cover, we have adopted a magnetic design to make assembly and disassembly more convenient.

More user-friendly design – The adjustable knob makes the height adjustment of the laser head more convenient, without any tools.

The principle of safety first – Our laser engraving machine has passed CE, FCC, RoHS, FDA, Weee, IEC 60825-1 certification, and also designed an emergency switch for easy power off at any time.

This machine can Laser Engrave and Laser Cutting Both Applications are on paper, wood, non-woven fabric, and thin plastic the bed size (working area) are 400 mm x 400mm. From a laser safety point of view, it is well designed to protect your eye you laser cut & laser engrave without goggles. Easily cut into a single pass. The spot laser size is 0.08mm which is very fine. Laser head automated lifting options.

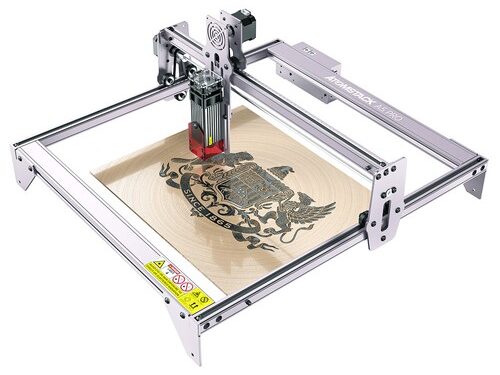

ATOMSTACK Laser Engraver

It is another amazing product for laser engraving and laser cutting machines, this machine body is made of aluminum alloy. This machine is equipped with high power of 10W, double laser head laser machine. Engraving area 410mm x 400mm. Do not require wearing gloss during laser work so save google cost and inconvenience of wearing. The laser machine body is made of 304, SS Mirror that helps to make laser cutting & engraving more accurate.

High-power laser made it easy to cut up to 20mm thick wood and 15mm thick acrylic in a single pass.

Important Factor To Keep in Mind Before Buying Laser Machine

There are numerous factors

Pros

- First Choice for Creative: Atomstack laser engraving machine can engrave various materials like metal, wood, bamboo, plastic

- Excellent Laser Engraving Technology: A5 Pro laser cutter with 5~5.5w output power with 0.16mm ultra-fine compression

- 180° Panoramic Visible:UV filter-retardant acrylic on laser module can filter 97% of the ultraviolet light, protecting your eyes and people around you

- High-Performance Structure Design: Atomstack A5 40W machine design with integrated screw rod

- Extensive Compatibility: The machine can be compatible with various mature engraving software, such as LaserGRBL(free)

Cons

2022 Upgraded ATOMSTACK A5 Pro

In fact, 20w/40w/50w/60w/90w is only the output power of the machine, not the key to determining the engraving/cutting effect. The output power of the laser module is the key point. If the output power of an engraving machine is 90W, and the output power of the laser module is 5~5.5w, That effect is not much different from that of a machine with a 40W output power and 5~5.5w laser module output power. you can choose which meets your needs.

ORTUR Laser Master 3

Pros

- First Choice for Creative: Atomstack laser engraving machine can engrave various materials like metal, wood, bamboo, plastic

- Excellent Laser Engraving Technology: A5 Pro laser cutter with 5~5.5w output power with 0.16mm ultra-fine compression

- 180° Panoramic Visible:UV filter-retardant acrylic on laser module can filter 97% of the ultraviolet light, protecting your eyes and people around you

- High-Performance Structure Design: Atomstack A5 40W machine design with integrated screw rod

- Extensive Compatibility: The machine can be compatible with various mature engraving software, such as LaserGRBL(free)

Cons

2022 Upgraded ATOMSTACK A5 Pro

In fact, 20w/40w/50w/60w/90w is only the output power of the machine, not the key to determining the engraving/cutting effect. The output power of the laser module is the key point. If the output power of an engraving machine is 90W, and the output power of the laser module is 5~5.5w, That effect is not much different from that of a machine with a 40W output power and 5~5.5w laser module output power. you can choose which meets your needs.

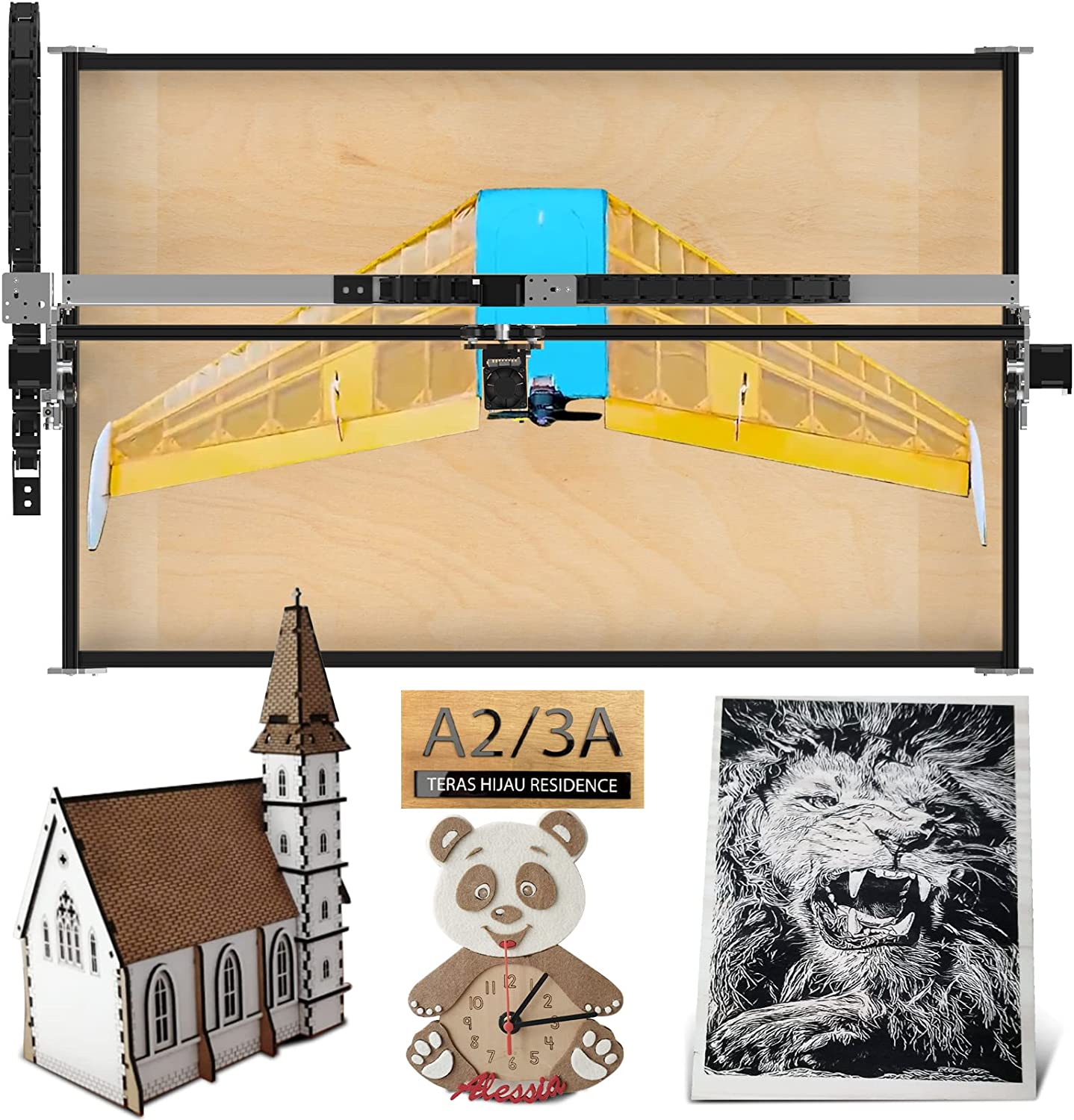

NEJE 3

Pros

- Top Engraving Capability

- Performance Improvement

- Large Engraving Area & Meet Various Engraving Needs

- Sturdy Structure & Easy Installation

- Extensive Software Compatibility

- Professional Technical Support & After Sales Service

Cons

NEJE 3 Max A40640 CUTTERING AND ENGRAVING SHOW

A40640 is a classic creative master dual beam zoom laser module, it is the first 2 beam laser diode engraving and cutting module with zoom design, with the best metal engraving ability, fast groove engraving ability, thick material cutting compatibility, make it the most widely used module. There are very special and top artistic expressions on the carvings of stainless steel grayscale carvings, stone carvings, Glass Carving, hardwood reliefs, canvas art, and other materials.

TEN-HIGH CO2 Engrave Machine

Pros

- Engraving Area

- Compatible with WIN7/WIN8/WIN10 system, 32-bit system is the most stable, also suitable for 64-bit. Software

- Pre-installed rotary axis interface and rotary axis switch (This machine Not Include rotary axis), easily extend to rotary engraving.

- To make sure choosing an appropriate machine, before placing order

Cons

This machine cannot engrave any metal. It can only engrave the anodized coating / non-metal surfaces).

There are two software can be used to drive the machine, Laser engraving Plug-in CorelLASER & Seal Design Software LaserDRW, which we all offer to our customers.

1. When use CorelLASER to drive the machine, you should installed the CorelDRAW first, because the CorelLASER is a laser engraving plug-in that plugs into CorelDRAW, So you can only start the CorelLASER after installing CorelDRAW. With this plugin, you can design graphics directly with CorelDRAW and engraving and cutting directly in CorelDRAW. We only provide the Laser engraving Plug-in CorelLASER, Don’t provide the drawing software CorelDRAW, so make sure that you have installed the right version CorelDRAW (the CorelDRAW 11, 12, X3, X4, X5, X6, X7 version all are available). Otherwise, you will not be able to use the CorelLASER drive engraving machine.

2. If you don’t have the right CorelDRAW software version, you can use LaserDRW we provided to drive our machine, but you need to making bitmaps in other packages and importing them into the LaserDRW software. In LaserDRW, you can directly open image files with extensions such as bmp, dib, jpg, jpeg, png, gif, wmf, emf, pcx, tif, tiff, etc.

Best brand

Laser Application Facts

- Laser marking application required a lower power supply than laser engraving and laser cutting starting, power supply starts from 5W to 150W maximum for the laser marking machine.

- Laser engraving on the metal up to 0.2-0.3 mm deep, power supply 30W -150W is sufficient even other stuff like wood & plastic required lower power supply.

- Laser cutting on metals sheet for fiber laser machine power supply min. must be 300W and a maximum of 8000W. It can cut up to 2mm thick metals and nonmetals 25 mm thick.

- Fiber laser is more effective compared to the co2 laser.

- Laser spot size comes 0.06-0.08 mm.

- The same laser power supplies affect differently on different stiffness characteristic substrates.

What is the basic factor that affects the quality of laser printing machines?

The laser focal lens, laser machine body structure, laser source supply, and power supply are the main key points to producing quality laser marking, engraving, and cuttings.

What are the materials we can’t engrave on it?

The drawback of laser engraving it can’t be applied on white, transparent, reflective, and translucent surfaces.

What is the light burn problem and how to resolve it?

During the engraving, sometimes laser light starts burning.