Pad Printing Machine Principle

What is pad printing? As it is clear by the name, pad printing is similar to the rubber-stamp with pad. But the difference is that stamp impression can be done only on the 2D substrate and pad printing application can be done on 2D and 3D substrates.

“The pad printing method is applied on the product shape made of complex design (3D) as well as circular, conical, cylindrical, convex, concave, and with the various angel, even, uneven, etc. (i.e. 3D, 2D, and intricate shape product).”

This printing application made enables print on a concave and convex surface easily. The printing application is likely different from other forms of traditional printing but more likely to the impression of the stamp.

In a simple way “In pad printing application, a 2D image design is transferred onto a 3D shape product.”

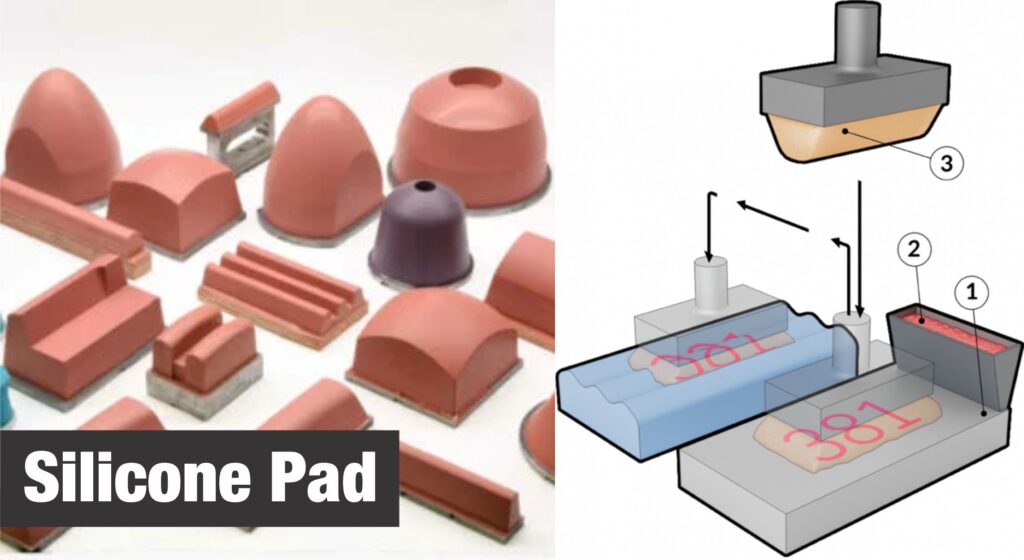

Pad printing application is involved in 3 main components.

Silicone Pad: The silicon pad comes in different shapes and sizes that play a major role to transfer data from the design engraved on the plate (cliche). Silicon material is able to adapt the shape of any hard stuff like a ball, toy, or pen and produce the impression of a print by applying pressure onto it.

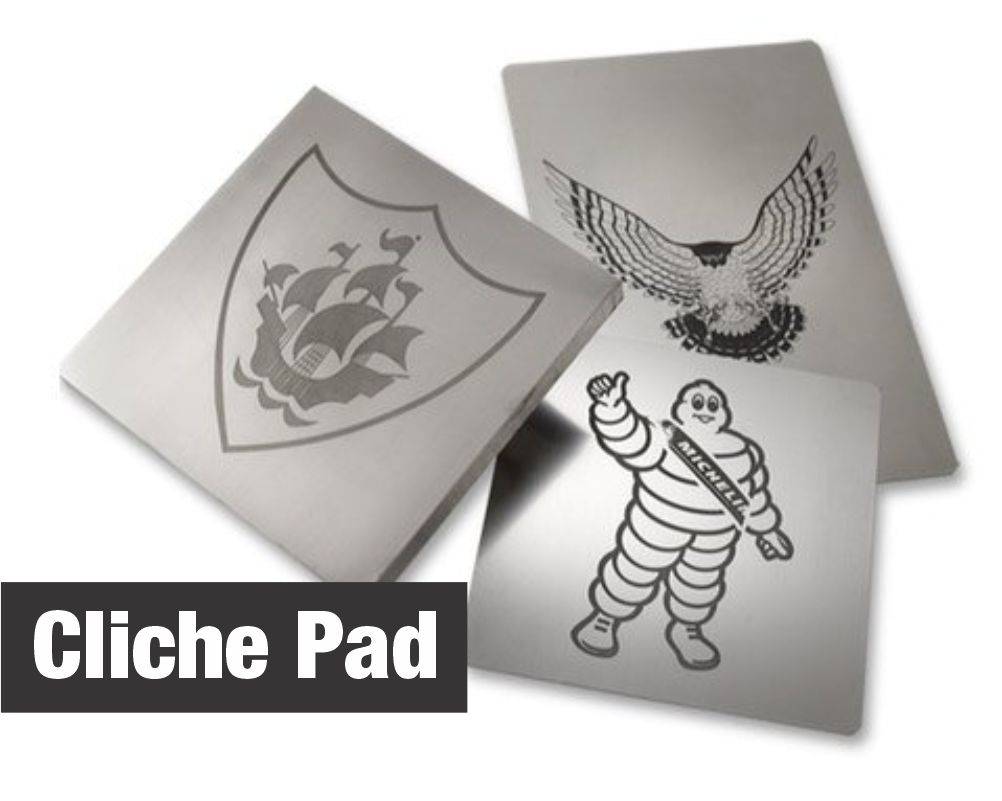

Cliche: A metal plate (thin stainless steel) with an engraved design to be printed on the intended product is known as a cliche.

Ink Cup: It holds the ink stock and releases ink amount only for each print required (likely in a micro ink amount) to fill the engraved design on the cliche.

Doctor Blade: Doctor blades help to swipe up all the excess ink on the cliche and restore it in the ink cup after each print is produced.

- Note: The silicone material has a technical tendency to adopt the shape if a little pressure is applied and recover its original shape if pressure is taken off.

Product What We Can Print in Pad Printing Machine

There is a huge list of products that get printed through pad printing applications in various industries such as Sports, Pharma, Auto Mobile, Electronic, Electricals, and Beverage Packaging.

- Crockery-Plates, Cups, and Water Bottles

- Sport-Volleyball, Cricket Ball, Pen, Base Ball, Watch Dial,

- Medical Appliance, Electrical Bulbs, Tube Light, and Many More…

- Beverage Packaging – Printing on Candy, Cake

Pad Printing Raw Materials

Pad printing machine is very simple to operate for producing a brand name on limited products. There are a few elements but each plays a crucial role as Cliche, Silicon Pad, Pad Printing Machine, Ink Cup, Doctor Blade, Pad Printing Ink, Computer, Laser Engraving Machine, and Ink Hardener.

For inline production, there is some complexity of UV light to make print dry fast.

Difference Between Pad Printing & Screen Printing

| Pad Printing | Screen Printing |

| 1. Pad printing required a metal plate to make a dye. | 1. The wooden or metal frame of the polyester screen |

| 2. The ink used is a 100% eco-friendly | 2. Harmful Printing ink |

| 3. It works for a 3D base product. | 3. This application is made for 2D base product printing |

| 4. To be placed for printing need to be product specific to fix on printing machines. | 4. Most of all products get printed on a flat surface |

| 5. Need to develop a design that requires laser engraving technology. | 5. Negative of positive film needed to develop for screen printing |

Type of Ink Used in Pad Printing

The ink used in pad printing is very viscous and fast drying. Due to high viscous ink, silicon picks up ink from the cliche easily and releases it on the substrate. Ink adhesion on the substrate is higher compared to silicon materials. There are different types of ink used as pigment base and dye-based. Inline pad printing production needed UV ink with a led curving mechanism to make print dry fast.

Q. How to make a pad printing plate

Ans. The Pad printing plate is made through laser engraving technology. It is a type of digital computerised service on the metal to create an image.

Just you need to make a vector design of the brand name or content to be printed on the substrate in a designing software like Corel or InDesign. Using a laser machine connected to the computer is engraved on the cliche. This engraved plate works for picking up the ink with the help of a silicon pad first and later on to the substrate.

Q. What is pad printing? and how does it work?

Ans. How does it work? Let’s understand in a few easy steps.

– Create a computerized design with the help of designing software Corel or photoshop etc.

– Engrave or etch an intended design on hard metal known as cliche through a laser engraving machine.

– Place the cliche in the pad printing machine in the right place.

– Pour the required ink color into a closed ink cup.

– Fill the ink on the engraved design on the cliche through a sliding ink cap.

– Pick up the ink from the cliche with a silicon pad by pressing it onto it.

– Place the intended substrate on the metal plate at the right position to make impression on it by making a slight pressure over the ink-picked silicon pad.

– Filled ink on the silicon pad releases the ink on the intended substrate with slight pressure.

– Let the printed product dry.

Move to the next cycle.