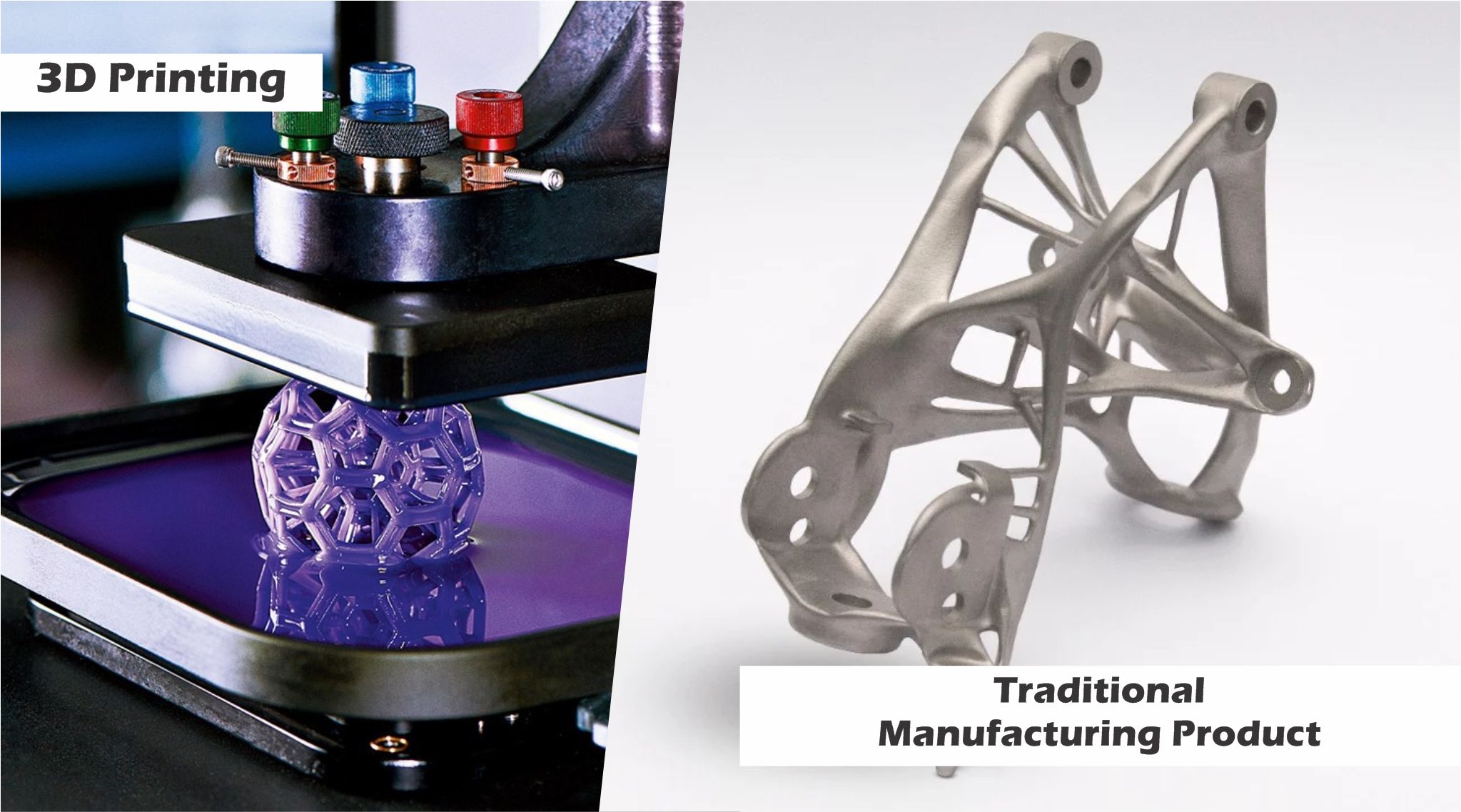

3D Printing vs Traditional Manufacturing Product

There is a huge variation in 3D printing vs traditional manufacturing products, due to the different types of 3d printing technologies requiring different types of materials as well as FDM, SLA, and SLS. Technologies that work for the best product refer to the different types of raw materials used for 3d printers.

FDM Technology

Works best for food, drink, and toy industries very cost-effective way for the production of small volume for small-scale business owners FDM technology printer is the best choice. This technology is typically used as a desktop home printer as a hobby or for creating models.

SLA Technology

In SLA technology, a type of printer works on polymer liquid and UV light-based. A solid plastic of 3 dimension is produced by applying UV light on curable polymers. The product’s quality is multiple times better in terms of product finish and strongness. This technology is most preferred in making medical science types of equipment for functional live cells. Ortho and donotics products for personalized parts of the human body are the most popular.

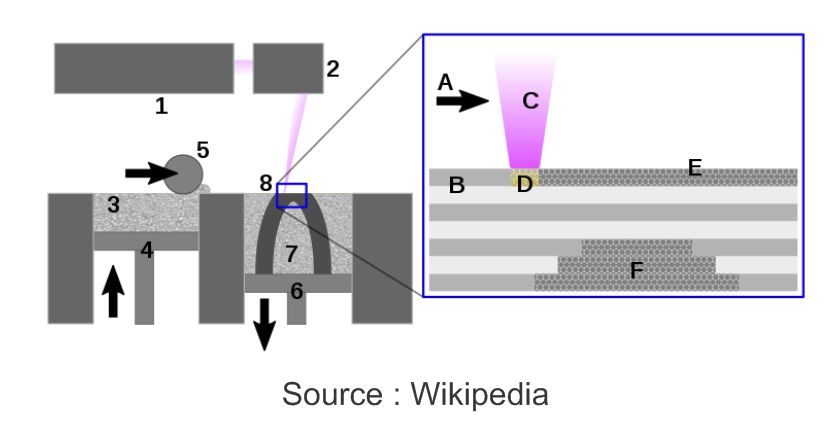

SLS Technologies

This technology refers to products made of metals created with the help of a laser beam, where metal powder forms a physical product. SLS printers are costly compared to other types of technology printers. Mostly these printers are highly used in commercial industries.

“SLS technology printer has a high-temperature element, metal powder, and high power laser beam generator, as the high-temperature help to melt metal powder at a specific position meanwhile a laser beam is diverted with the help of a mirror to control the same location to harden the melted material in the 3 dimensions”

Quality is made for printing specific types of technology printing. The raw material used in 3D printing is plastic wire, liquid polymer, and metal powder.

3d Technology is based on UV light, Laser Beam, and Fused Deposit Materials. FDM technology-based 3D prints are very cheap and starting range starts from Rs. 20,000 and above can be used as a home desktop printer. There are various reasons to buy a 3D printer. You need to check your exact requirement before buying the 3D printer.